PROJECT HIGHLIGHTS:

- 871.8 million tonne Inferred Mineral Resource including 2.01 kg/t TREO, plus niobium and phosphate.

- 15.6 million tonne Indicated Mineral Resource including 1.67 kg/t total rare earth oxides (“TREO”), plus niobium and phosphate.

- Situated in Ontario, Canada, a stable, mining friendly, jurisdiction – a potential key North American source of Critical Minerals to meet an anticipated enormous expansion in demand for such products.

- Substantial potential remains to expand and upgrade the initial Mineral Resource Estimate.

- Project is exceptionally located in Ontario, Canada close to the TransCanada Highway, rail, power, and shipping infrastructure.

- Preliminary Economic Assessment to commence shortly.

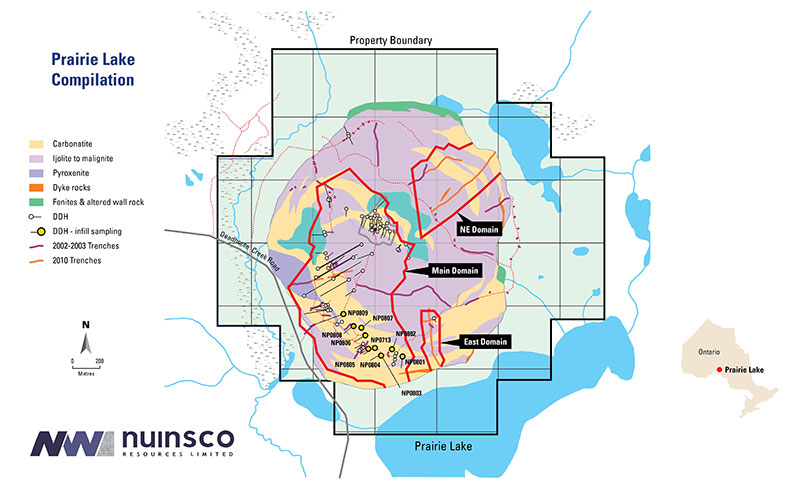

Nuinsco’s 100%-owned Prairie Lake Critical Minerals and Phosphate Project covers the entire 2.8 km² area (at surface) of the Prairie Lake Carbonatite Complex. The Prairie Lake Carbonatite Complex is an approximately 1160-million-year-old carbonatite-alkali intrusion emplaced into fractured and faulted continental shield rocks with the Trans Superior Tectonic Zone.

The Property is located just 28 km north of the Trans-Canada Highway Located and 45 km northwest of town of Marathon, Ontario. The Project benefits from a location in a politically stable jurisdiction; there is year-round road access; it is exceptionally well located near available rail, road, shipping, and power infrastructure; and is ideally placed in North America with respect to current supply chain concerns for critical minerals.

In May 2022, an initial Mineral Resource Estimate (MRE) was completed on the Property. As tabulated below, the pit constrained MRE consists of a 15.6 million tonne Indicated Mineral Resource and a very large 871.8 million tonne Inferred Mineral Resource. The MRE also includes niobium and phosphate in oxides which, along with the TREO, are expected to be key drivers of a Preliminary Economic Assessment on the Project that will commence shortly.

Prairie Lake Project Pit Constrained Mineral Resource Estimate(1-6)

| Rare Earth Oxides | Niob-ium | Phos-phate | |||||||||||

| Class | Cut-Off | Tonnes | Nd2O3 | Pr6O11 | Sc2O3 | CeO2 | La2O3 | Sm2O3 | Ta2O5 | Y2O3 | TREO | Nb2O5 | P2O5 |

| NSR C$/t | M | g/t | g/t | g/t | g/t | g/t | g/t | g/t | g/t | kg/t | % | % | |

| Indicated | 30 | 15.6 | 344 | 96 | 15 | 754 | 300 | 58 | 28 | 100 | 1.67 | 0.16 | 3.71 |

| Inferred | 30 | 871.8 | 409 | 82 | 18 | 905 | 388 | 79 | 17 | 127 | 2.01 | 0.10 | 3.39 |

*TREO = Total Rare Earth Oxides: neodymium, Nd2O3 ; praseodymium, Pr6O11; scandium, Sc2O3; Cerium, CeO2; lanthanum, La2O3; samarium, Sm2O3; tantalum, Ta2O5; yttrium, Y2O3.

- Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability.

- The estimate of Mineral Resources may be materially affected by environmental, permitting, legal, title, taxation, socio-political, marketing, or other relevant issues.

- The Inferred Mineral Resource in this estimate has a lower level of confidence than that applied to an Indicated Mineral Resource and must not be converted to a Mineral Reserve. It is reasonably expected that the majority of the Inferred Mineral Resource could potentially be upgraded to an Indicated Mineral Resource with continued exploration.

- The Mineral Resources were estimated in accordance with the Canadian Institute of Mining, Metallurgy and Petroleum (CIM), CIM Standards on Mineral Resources and Reserves, Definitions (2014) and Best Practices Guidelines (2019) prepared by the CIM Standing Committee on Reserve Definitions and adopted by the CIM Council.

- US$ Metal prices used were $80,000/t Nd2O3, $80,000/t Pr6O11, $1,500,000/t Sc2O3, $50,000/t Nb2O5, $250/t P2O5, $1,350/t CeO2, $1,350/t La2O3, $3,500/t Sm2O3, Nil$/t Ta2O5 and $13,000/t Y2O3, 0.78 FX all with combined process recoveries and payables of 50%, except P2O5 at 75%.

- The constraining pit optimization parameters were C$2.50/t mining cost for all material, C$25/t process cost, C$5/t G&A cost and 45-degree pit slopes with a C$30/t NSR cut-off.

The mineralization of economic interest contained within the Prairie Lake complex occurs at surface and extends to unknown depths below the deepest drilling yet conducted (circa 525 metres vertically). There is no indication that mineralization diminishes with depth and is known to occur at surface throughout the extents of the complex.

Prairie Lake Project Mineral Resource Estimate Sensitivity to NSR Cut-Off

| Class | Cut-Off | Tonnes | Nd2O3 | Pr6O11 | Sc2O3 | CeO2 | La2O3 | Sm2O3 | Ta2O5 | Y2O3 | TREO* | Nb2O5 | P2O5 |

| NSR C$/t | M | g/t | g/t | g/t | g/t | g/t | g/t | g/t | g/t | kg/t | % | % | |

| Indicated | 50 | 14.5 | 358 | 100 | 16 | 787 | 306 | 60 | 28 | 101 | 1.73 | 0.17 | 3.75 |

| 40 | 15.2 | 349 | 98 | 15 | 766 | 302 | 59 | 28 | 101 | 1.69 | 0.17 | 3.73 | |

| 30 | 15.6 | 344 | 96 | 15 | 754 | 300 | 58 | 28 | 100 | 1.67 | 0.16 | 3.71 | |

| 20 | 15.7 | 343 | 96 | 15 | 751 | 300 | 58 | 27 | 100 | 1.66 | 0.16 | 3.70 | |

| 10 | 15.7 | 343 | 96 | 15 | 751 | 300 | 58 | 27 | 100 | 1.66 | 0.16 | 3.70 | |

| Inferred | 50 | 815.1 | 419 | 83 | 19 | 930 | 394 | 81 | 17 | 127 | 2.06 | 0.10 | 3.43 |

| 40 | 860.1 | 412 | 82 | 19 | 911 | 389 | 80 | 17 | 128 | 2.02 | 0.10 | 3.40 | |

| 30 | 871.8 | 409 | 82 | 18 | 905 | 388 | 79 | 17 | 127 | 2.01 | 0.10 | 3.39 | |

| 20 | 873.4 | 409 | 82 | 18 | 904 | 387 | 79 | 17 | 127 | 2.01 | 0.10 | 3.38 | |

| 10 | 873.5 | 409 | 82 | 18 | 904 | 387 | 79 | 17 | 127 | 2.01 | 0.10 | 3.38 |

The MRE for the Prairie Lake project is based on 73 inclined diamond drill holes performed between 1969 and 2010 totalling 12,180 metres. Additionally, 2,068 metres of surface trenching is included in the Mineral Resource Estimate. A total of 5,409 drill core samples and 1,042 channel samples are incorporated into the MRE, excluding QA/QC samples. A length of 1.5 metres was used for composites and they were capped as follows: 1,850 g/t Nd2O3, 250 g/t Pr6O11, no cap Sc2O3, 1% Nb2O5, 14% P2O5, 3,700 g/t CeO2, 1,700 g/t La2O3, 520 g/t Sm2O3, no cap Ta2O5 and 570 g/t Y2O3. Grade interpolation was undertaken with the ID2 method on 10m x 10m x 10m blocks. Indicated Mineral Resources were classified within a 55m x 55m x 40m search ellipse and three drill holes while Inferred Mineral Resources were classified in two passes with a 110m x 110m x 80m search ellipse with two drill holes and a 220m x 220 m x 160m search ellipse with one drill hole.

The mineralization is exposed at surface and could initially be exploited by quarrying methods. The proportion of the surface area of the Prairie Lake Complex that has been significantly explored provides ample room to expand the MRE.

To date process testing has succeeded in producing phosphate concentrate to >30% P2O5. In producing a phosphate concentrate a REE con is also produced as the phosphate and REEs reside in the same mineral (apatite) to a great extent. As noted, the suite of minerals of potentially economic significance also includes niobium (Nb2O5), tantalum (Ta2O5).

Nuinsco has already demonstrated that high-quality phosphate and niobium concentrate can be produced from Prairie Lake mineralization. The suite of economically significant mineralization identified in the MRE includes neodymium, praseodymium, niobium, scandium, and phosphate; demand for all is projected to steeply increase over the coming years through expanding electrification and implementation of “green” technologies to combat climate change, and to sustain and improve agricultural productivity globally. The Project benefits from being in a politically stable jurisdiction; is exceptionally located near to available rail, road, shipping, and power infrastructure; and is ideally placed in North America with respect to current supply chain concerns for critical minerals.

| Prairie Lake technical report | |

| Prairie Lake presentation |